Navigate Hard Surface: Why Choosing the Right Undercarriage Parts Matters

Navigate Hard Surface: Why Choosing the Right Undercarriage Parts Matters

Blog Article

Discover Undercarriage Components for Heavy Machinery

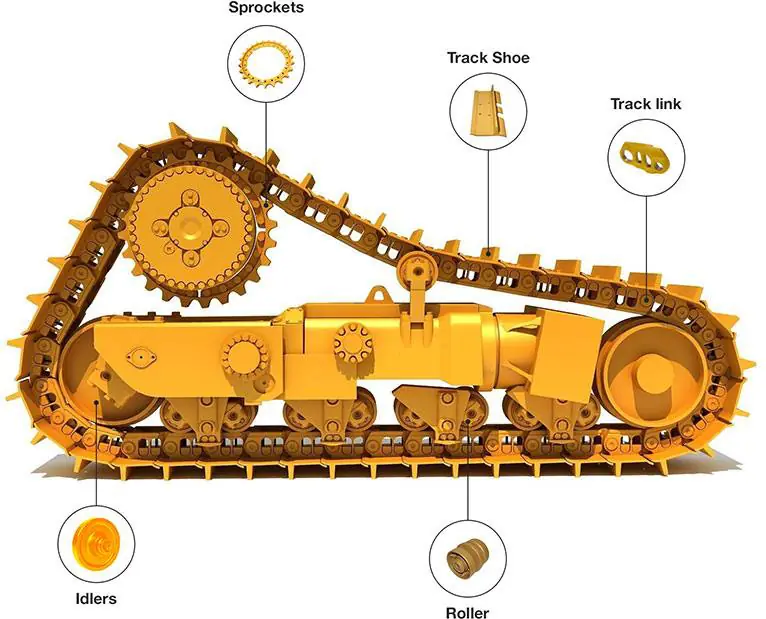

Understanding the complexities of undercarriage components is crucial for the optimal performance and durability of heavy machinery. From track shoes to idlers, gears, and rollers, each component plays an essential duty in the performance of the equipment.

Value of Undercarriage Components

The undercarriage components of heavy machinery play an essential duty in making sure the total performance and long life of the tools. These components, consisting of tracks, rollers, idlers, chains, and sprockets, develop the structure whereupon the device operates. A properly maintained undercarriage not just supplies security and support to the hefty equipment yet likewise adds significantly to its operational performance and performance.

One of the crucial advantages of spending in high-grade undercarriage parts is the reduction of downtime and maintenance expenses. By utilizing sturdy components that can stand up to the roughness of sturdy applications, drivers can lessen the requirement for regular repairs and substitutes, hence maximizing the maker's uptime and general life-span.

Additionally, properly operating undercarriage parts guarantee optimum weight ability to move, traction, and circulation, enabling the heavy equipment to run smoothly even in tough terrains. This reliability is crucial for markets such as mining, agriculture, and construction, where tools performance straight affects job timelines and success. In conclusion, the relevance of undercarriage components can not be overemphasized in maintaining the performance and longevity of hefty machinery.

Kinds of Track Shoes

When considering the numerous kinds of track shoes for hefty equipment, it is important to examine their style and capability in relation to specific functional demands. Track shoes are essential elements of the undercarriage system, supplying security, traction, and weight circulation for heavy machinery such as excavators, excavators, and crawler cranes.

One of the most usual kinds of track shoes include:

** Grouser Shoes **: Featuring elevated steel bars (grousers) along the footwear's surface, these track footwear give boosted grip in tough terrains like mud, snow, and loose gravel. undercarriage parts.

** Double Grouser Shoes **: Comparable to grouser footwear but with an extra collection of grousers, these track footwear offer even better traction and stability, making them perfect for extremely harsh terrains.

** Triple Grouser Shoes **: With three sets of grousers, these track footwear give maximum grip and stability, making them suitable for the most requiring problems.

Selecting the appropriate sort of track shoe is important for optimizing the efficiency and long life of hefty machinery while making certain security and effectiveness throughout operations.

Feature of Rollers and Idlers

Rollers and idlers play important functions in supporting and leading the track shoes of hefty equipment during operation. Rollers are cylindrical elements that sustain the weight of the tools click here for more and guarantee smooth activity along the terrain. They aid distribute the machine's weight evenly, minimizing endure the track footwear and lessening resonances. Idlers, on the other hand, overview the track chain and help maintain appropriate tension. By avoiding extreme slack or rigidity in the tracks, idlers add to the overall security and performance of the equipment (undercarriage parts).

Additionally, rollers and idlers interact to maintain the track footwear in placement, stopping them from thwarting or slipping off during operation. Properly operating rollers and idlers are critical for guaranteeing the durability of the undercarriage system and making the most of the machine's effectiveness. Regular maintenance and examination of these elements are important to identify any kind of indicators of wear or damage early, preventing expensive repairs and downtime over time.

Duty of Sprockets in Machinery

Maintenance Tips for Undercarriage Elements

Reliable upkeep of undercarriage components is necessary for ensuring the long life and optimal performance of hefty equipment. Routine evaluation of undercarriage components such as track chains, rollers, idlers, sprockets, and track footwear is important to prevent costly repair services and unanticipated failures. One vital upkeep tip is to keep the undercarriage tidy from particles, mud, and various other contaminants that can increase wear and corrosion. It is additionally vital to make sure correct track stress to prevent premature endure elements. Oiling the undercarriage parts at recommended intervals assists to decrease friction and expand the lifespan of the parts. Checking for any unusual noises, vibrations, or adjustments in device efficiency can indicate possible concerns with the undercarriage that require instant attention. By complying with these maintenance pointers faithfully, hefty machinery drivers can decrease downtime, minimize operating costs, and make best use of the efficiency of their tools.

Conclusion

Finally, the undercarriage components of hefty equipment play a vital function in making sure the smooth performance and durability of the equipment. More about the author Comprehending the relevance of track footwear, gears, rollers, and idlers, in addition to applying appropriate maintenance techniques, can greatly influence the overall efficiency and performance of the equipment (undercarriage parts). Regular evaluation and timely replacement of damaged parts are vital in optimizing the life-span and performance of hefty machinery

Rollers and idlers play essential duties in sustaining and assisting the track shoes of heavy equipment during operation.In hefty machinery, gears offer a crucial function in transferring power from the engine to the tracks, making it possible for the equipment to relocate efficiently and successfully. These parts are connected to the axles or last drives of the equipment and work in combination with the tracks to move the devices ahead or backwards. Normal inspection of undercarriage components such as track chains, rollers, idlers, gears, and track footwear is crucial to avoid unanticipated malfunctions and expensive repair services. Comprehending the significance of track footwear, gears, idlers, and rollers, as well as carrying out appropriate maintenance practices, can greatly impact the general performance and efficiency of the machinery.

Report this page